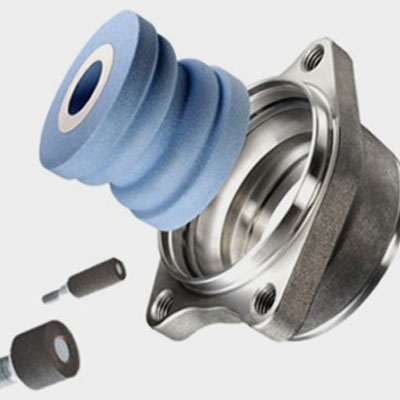

Description:

Internal Grinding Wheel uses high-quality raw materials, maintains good shape accuracy during the grinding process, has good surface roughness, and has a long service life. Widely used for processing inner and outer diameters of bearings, small diameter cylinders, valve components, constant velocity universal joint components, etc.

Application:

1. Connecting rod end grinding in the automotive industry.

2. Grinding of hydraulic and pneumatic cylinders.

3. CVJ ball joints, inner and outer raceways.

4. Hydraulic tappets in automotive motors.

5. Grinding inner race bores.

6. Grinding gear bores and collection.

7. Grinding stators and barrels in automotive pumps.

8. Grinding rollers, cylinders, and flange covers for air conditioning compressors.

9. Grinding the inner and outer surfaces of ball and roller bearings.

Technical Parameters:

| Abrasive | Size | Binder | Additives | Surface Roughness | Grinding Wheel Speed | Roughness After Polishing | Processing Time | Processing | Lifetime | Work Speed (RPM) | SKIP Number | Roller Dressing |

| CBN、SG、SA RA、WA、A |

Φ10~50x 10~50XΦ06~25 |

V: Ceramic | S: Sulfur 2W: Wax | Ra 0.63/Rz 3.0μm↓ | 60m/s (24000rpm)↓ | Ra 0.1/Rz 0.7μm↓ | 10-50sec | Φ0.1-0.2mm | 300-24000 | 300-3000RPM | 3-100 | 80m/s↓ |

Photos:

Click directly to send a message via WhatsApp

Click directly to send a message via WhatsApp